Auto accessory molds play a vital role in the automotive industry, acting as the backbone of the manufacturing process for various interior and exterior components. These molds are essential for producing parts such as dashboard panels, air vents, door trims, center consoles, mudguards, mirror housings, and more. Auto accessory molds are typically created using high-grade steel or aluminum and are designed through precision CNC machining, EDM processing, and strict quality control systems to ensure consistency, durability, and accuracy.

The increasing demand for personalized, lightweight, and eco-friendly vehicle components has driven innovation in mold design and injection molding technologies. Today, automotive mold manufacturers are investing heavily in automotive interior trim mold solutions that offer superior aesthetics and functionality, helping brands deliver high-quality, consumer-focused vehicle accessories.

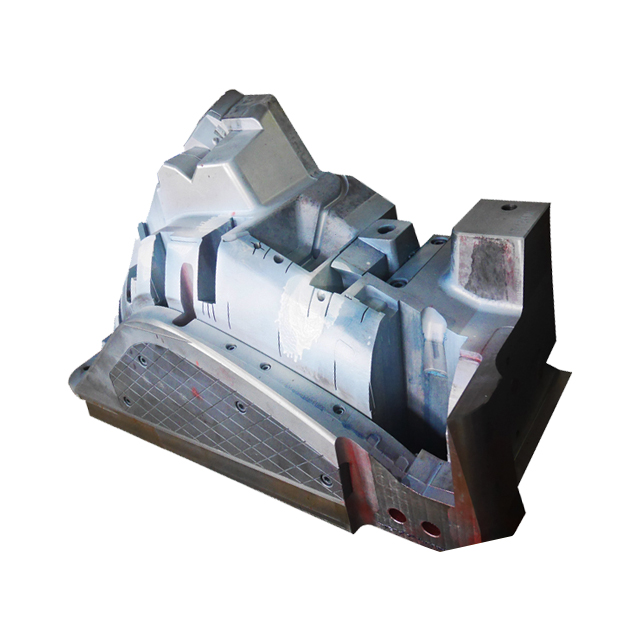

Automotive Plastic Injection Mold

Frequently Asked Questions (FAQs) About Auto Accessory Mold

What is an Auto Accessory Mold?

An auto accessory mold is a customized mold tool used to produce automotive accessories through plastic injection molding or other molding processes, such as compression molding or blow molding. These accessories range from small plastic buttons to large dashboard structures.

Auto accessory molds are specifically engineered to meet the complex geometries, surface finish requirements, and structural tolerances demanded by modern automotive parts. Precision tooling ensures that every molded component fits perfectly into a vehicle's system, whether functional or aesthetic.

What Materials Are Commonly Used in Auto Accessory Molds?

Auto accessory molds are typically manufactured using:

● P20 Steel: Good for general-purpose plastic molds with moderate volume.

● H13 Steel: High strength, ideal for high-volume production with demanding cycle times.

● S136 Stainless Steel: Used for molds requiring high polish and corrosion resistance.

● Aluminum: Lightweight and suitable for prototyping or low-volume runs.

The choice of mold material often depends on the type of automotive plastic parts being produced, volume of production, and surface finish requirements. Materials like ABS, PC+ABS, polypropylene (PP), and thermoplastic elastomers (TPE) are frequently used for molded parts.

What Are the Key Design Considerations in Auto Accessory Mold Making?

Mold design for auto accessories involves several critical elements:

● Draft Angles: To enable easy part release.

● Wall Thickness: Uniformity to prevent warping and shrinkage.

● Gate Location: Optimal placement ensures uniform material flow.

● Cooling System Design: Effective cooling reduces cycle time and improves quality.

● Ventilation: To release trapped air and avoid short shots or burn marks.

A reputable automotive injection mold manufacturer will also use software like CAD/CAE/UG/NX for mold flow analysis to simulate filling, packing, cooling, and warping processes, ensuring design reliability before tooling begins.

What Types of Auto Accessory Molds Are Available?

Auto accessory molds are typically categorized based on application and component type:

● Interior Trim Molds: For dashboard, center consoles, door panels, glove boxes.

● Exterior Accessory Molds: For mudguards, grilles, side mirrors, and bumpers.

● Functional Component Molds: For brackets, clips, fasteners, and air ducts.

● Lighting Component Molds: For lamp housings, lens covers, band zels.

Injection molding remains the most widely used manufacturing process due to its precision, repeatability, and cost-effectiveness for high-volume runs.

How Long Does It Take to Make an Auto Accessory Mold?

The time required for mold manufacturing depends on several factors:

● Part complexity

● Size of the mold

● Mold type (prototype vs production mold)

● Number of cavities

On average, producing a medium-complexity automotive plastic injection mold may take between 4 to 12 weeks. Prototyping tools may take less time, typically 2 to 4 weeks. However, design validation, testing, and adjustments may extend the timeline slightly.

How to Choose the Right Auto Accessory Mold Manufacturer?

When sourcing a mold maker, consider the following:

● Experience in Automotive Tooling: Ensure the manufacturer specializes in automotive accessory mold fabrication.

● Engineering Capabilities: CAD/CAE capabilities and DFM (Design for Manufacturing) services.

● In-house Production: From mold design to polishing and trial injection.

● Quality Certifications: ISO 9001, IATF 16949 indicate a strong quality management system.

● After-Sales Support: Ongoing maintenance, modification services, and part validation.

Leading China auto accessory mold manufacturers often offer one-stop solutions with competitive pricing and fast lead times while maintaining global quality standards.

What Are the Common Defects in Auto Accessory Injection Molding?

Some frequently encountered defects include:

● Flow lines or weld lines due to inconsistent filling.

● Warping from uneven cooling or part design issues.

● Sink marks caused by thick wall sections.

● Short shots occur when mold cavities aren’t filled.

● Burn marks from trapped air or overheating.

Working closely with a skilled automotive injection mold supplier can help you optimize mold design and process parameters to avoid these defects.

Can Molds Be Modified After Production?

Yes, most molds can be modified to a certain extent. Common modifications include:

● Adding or removing venting

● Adjusting parting lines

● Polishing for a better surface finish

● Altering ejector pin layouts

● Replacing inserts

However, mold modifications should be discussed during the design stage to avoid high costs and long downtimes during production.

What Is the Lifespan of an Auto Accessory Mold?

A high-quality mold can last from 100,000 to over 1 million cycles, depending on:

● Mold material

● Maintenance frequency

● Injection pressure

● Type of plastic used

Molds made of hardened steel (like H13) can last significantly longer than aluminum prototype molds. Regular cleaning, lubrication, and inspection are key to extending the mold life cycle.

What Are the Recent Trends in Auto Accessory Mold Design?

Recent industry trends include:

● Lightweight Components: Using engineering plastics instead of metal to reduce vehicle weight.

● Soft-touch Finishes: Overmolding TPE or TPU on rigid plastics for premium interiors.

● Smart Molds: Integration of sensors to monitor temperature, pressure, and wear in real time.

● Multi-shot Molding: Enables complex designs and multi-color parts without secondary assembly.

● Sustainable Design: Use of recycled materials and molds designed for minimal waste production.

Conclusion

Understanding auto accessory molds helps you make better decisions when designing, sourcing, or manufacturing automotive parts. From selecting the right materials and mold design to choosing a reliable auto mold manufacturer, every step plays a crucial role in the quality and performance of the final components. Whether you're developing next-generation electric vehicles or looking to upgrade interior styling, investing in advanced auto accessory molding solutions will ensure consistent product quality and customer satisfaction.

RUNKE is committed to providing high-quality auto accessory molds to help you produce automotive parts that meet high-performance and reliability standards. Contact us to get exclusive custom solutions for your auto accessory molds.

.jpg)

.jpg)