The motorcycle helmet molding process is an important step in the production of high-quality motorcycle helmets. The process involves creating a mold that is used to shape the outer shell of the helmet.

What Is a Motorcycle Helmet Mold?

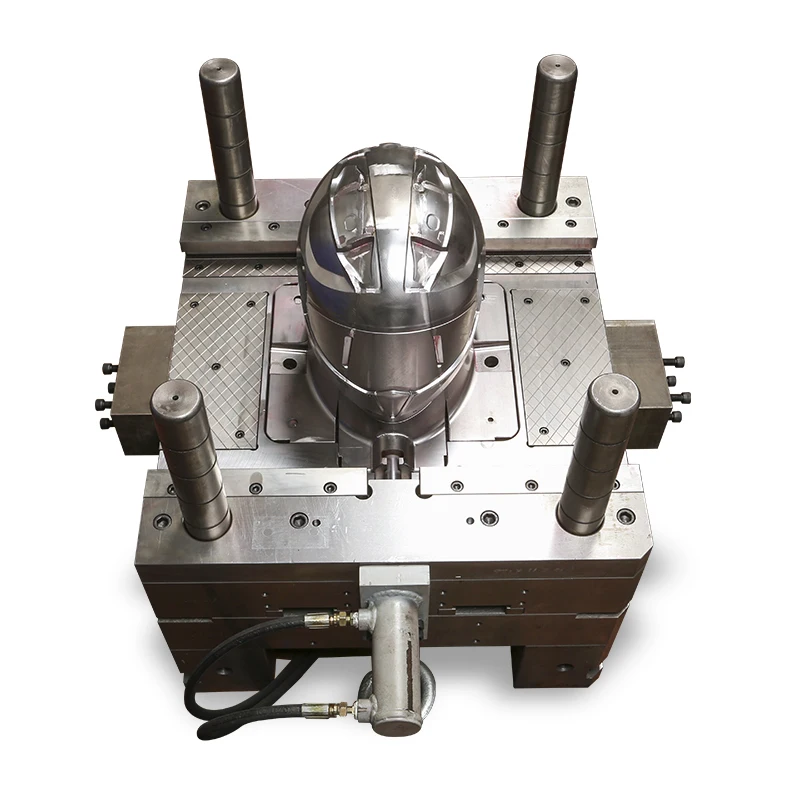

A motorcycle helmet mold is a tool used in the manufacturing process of motorcycle helmets.

A motorcycle helmet mold is a three-dimensional object, typically made of metal, plastic, or other materials, which is used to shape the outer shell of the helmet.

In modern manufacturing, plastic motorcycle helmet molds are widely used due to their versatility and cost-effectiveness. These molds must be engineered with high precision to ensure that the resulting helmet is safe, comfortable, and aerodynamic. Especially in the case of carbon fiber helmets motorcycle molding process, the mold must withstand high temperatures and pressures while maintaining dimensional accuracy.

The Role of Motorcycle Helmet Mold

The motorcycle helmet mold plays a critical role in the production of high-quality motorcycle helmets.

Motorcycle helmet mold is created to replicate the exact shape and size of a particular helmet design, and it is used to form the helmet shell from materials such as polycarbonate, fiberglass, or carbon fiber. Once the shell is formed, the helmet's internal components, such as the liner, chinstrap, and visor, are installed.

In the motorcycle molding process, precision is everything. A well-crafted mold allows for the consistent creation of molded motorcycle helmets that meet rigorous safety standards. With innovations in mold design, it’s now possible to integrate complex features such as aerodynamic vents, reinforced chin bars, and contoured visors directly into the helmet shell.

Importance of Using Motorcycle Helmet Mold

Using a mold to create motorcycle helmet shells is an important part of the manufacturing process, as it helps to ensure that the helmet provides the necessary level of protection for riders.

The use of a plastic motorcycle helmet mold in the motorcycle helmet molding process ensures that each helmet is made to exact specifications, which helps to ensure consistency and quality in the manufacturing process.

By using a motorcycle helmet mold, helmet manufacturers can create helmets that are uniform in shape and size, and that meet the same high standards of safety and durability.

This is especially vital for producing custom molded motorcycle helmets, which are tailored for specific users or markets. Custom molds ensure that features such as fit, ventilation, and impact resistance are optimized for individual preferences or use cases, such as racing or touring.

Motorcycle Plastic Mold Manufacturer: Custom Molded Motorcycle Helmets

Motorcycle helmet molds are an important factor in ensuring the safety of riders, as they help to create helmets that are strong and durable.

To create a motorcycle helmet using a mold, the helmet manufacturer will typically start by selecting the appropriate mold for the particular helmet design. Therefore, choosing reliable motorcycle plastic mold manufacturers will be something not to be underestimated.

Motorcycle plastic mold manufacturers play a key role in ensuring riders are protected. Motorcycle plastic mold manufacturers use a variety of materials and techniques to create molds that are both durable and precise, ensuring that each product they produce meets the standards of quality and safety.

RUNKE MOLD - As one of the motorcycle plastic mold manufacturers in China, maybe you can find more details of motorcycle helmet visor mold here.

High-Quality Motorcycle Plastic Molds for Superior Performance

RUNKE Mold specializes in manufacturing motorcycle plastic molds designed to meet the highest industry standards. Our products ensure precision and durability for various motorcycle components, including motorcycle helmet molds, injection motorcycle parts molds, and motorcycle parts plastic molds.

With advanced ABS injection molding technology, we create reliable and lightweight solutions like ABS injection molding motorcycle fairings and plastic motorcycle helmet molds. Each mold is tailored to meet your specific needs, providing consistent quality for your production line.

Whether you require custom molds for motorcycle parts or specialized solutions for helmet production, Runke Mold delivers exceptional craftsmanship and fast production turnaround. Partner with us for premium-quality molds that support your manufacturing success. Explore our range of plastic molds for motorcycles and elevate your production efficiency today!

.jpg)

.jpg)

.jpg)