In today's automotive manufacturing industry, innovation and efficiency are driven not only by advances in drivetrain technology or vehicle electronics, but also by how car components and accessories are designed and produced. One of the most critical processes supporting this evolution is automotive accessory injection molding — a specialized subset of plastic injection molding that focuses on producing high-precision and durable vehicle accessories.

Automotive Accessory Injection Molding

Automotive accessory injection molding refers to the process of manufacturing various interior and exterior automotive components using thermoplastic or thermoset materials. These accessories include parts like cup holders, dashboard panels, mirror housings, console components, air vents, door trims, and more.

The process uses specialized molds, high-tonnage injection molding machines, and precise material formulations to achieve the dimensional accuracy, texture, and strength needed in automotive environments. Leading automotive injection molding manufacturers utilize computer-aided design (CAD), simulation software, and automation to meet stringent OEM standards.

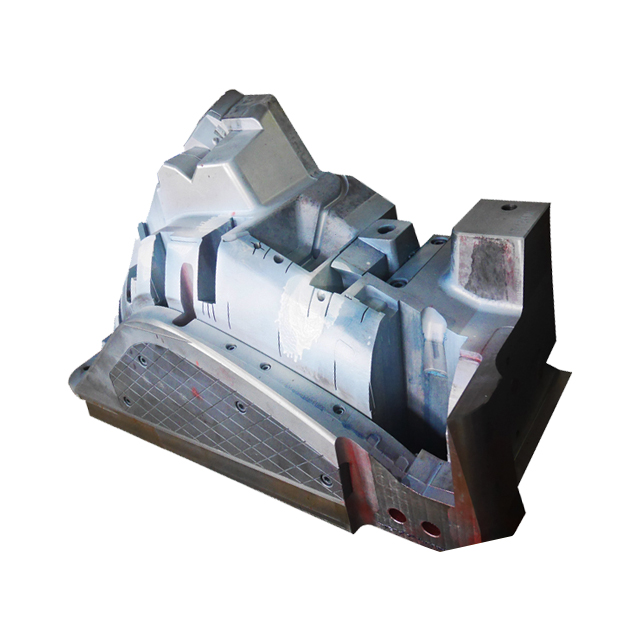

Automotive Accessory Injection Mold

Key Components Produced Using Injection Molding

Some of the most common automotive plastic accessories produced using this process include:

● Dashboard and instrument panels

● Interior trims and door panels

● Center console components

● Air conditioning vents and knobs

● Exterior mirror housings

● Grilles and bumper trims

● Car floor clips and brackets

● Lighting bezels and reflectors

● Custom automotive parts (designed for aftermarket solutions)

These parts need to meet not only functional requirements but also aesthetic ones. Many of them are visible to drivers and passengers, making precision molding and surface finishing crucial to success.

Advantages of Injection Molding for Automotive Accessories

Several advantages drive the growing preference for injection molding in the automotive accessories sector:

1. High Repeatability and Precision: Injection molding ensures that every piece produced is nearly identical to the last, which is essential for large-volume production where parts must fit perfectly into existing vehicle structures.

2. Cost Efficiency for Mass Production: While the initial cost for mold creation can be high, the unit cost drops dramatically in large production runs. This makes custom automotive accessory manufacturing viable and scalable.

3. Material Versatility: Automotive accessory injection molding supports a wide range of engineering-grade plastics, such as:

● ABS (Acrylonitrile Butadiene Styrene)

● Polycarbonate (PC)

● Polypropylene (PP)

● POM (Polyoxymethylene)

● Thermoplastic Elastomers (TPE)

Each material offers unique properties, such as heat resistance, impact strength, and flexibility, which are vital for various automotive accessory applications.

4. Lightweighting Benefits: Plastic components significantly reduce the vehicle's overall weight compared to metal parts, contributing to improved fuel efficiency and lower emissions—a key trend in automotive sustainability solutions.

5. Design Flexibility: Injection molding enables the production of intricate geometries, integrated clips, and functional features directly into the mold. This is particularly advantageous for ergonomic automotive designs and futuristic interiors.

Trends in Automotive Accessory Design via Injection Molding

1. Smart Integration: Modern car interiors now feature integrated smart accessories such as wireless charging modules, ambient lighting diffusers, and sensor mounts. Injection molding supports these features by embedding cavities or channels directly into the part design.

2. Soft-Touch and Multi-Material Molding: To improve user experience, soft-touch finishes and two-shot molding techniques are used to combine rigid and soft polymers in the same part, such as armrests or steering wheel trim.

3. Sustainable Materials: Automotive OEMs and accessory manufacturers are increasingly using bioplastics or recycled polymers for injection molding as part of their green initiatives.

Applications of Injection Molded Automotive Accessories

These components are found across multiple vehicle systems:

● Passenger cabin: cup holders, storage compartments, seatbelt covers

● Engine bay: cable guides, battery brackets

● Exterior trims: fog light housings, rear spoilers

● Infotainment systems: housing for screens, control panels

In electric vehicle (EV) accessory design, molded parts are used for wire harness routing, charge port mounts, and sensor covers.

As vehicles become smarter and more efficient, automotive accessory injection molding will play a growing role in providing both functional and aesthetic enhancements. Trends such as lightweight materials, modular interiors, and connected vehicle accessory solutions will continue to push innovation in this space.

By integrating electronics, utilizing sustainable materials, and embracing design for manufacturability (DFM), the next generation of automotive accessories will offer better performance, safety, and personalization options.

Conclusion

Automotive accessory injection molding is more than just a manufacturing technique—it's a critical enabler of modern car design. With its precision, scalability, and adaptability to both OEM and aftermarket needs, this process is set to remain indispensable in the evolving automotive landscape.

Whether you're designing a futuristic cockpit or engineering a durable under-hood bracket, injection molding offers the versatility, quality, and cost-efficiency that today's automotive industry demands.

.jpg)

.jpg)