When we think about modern cars, we usually focus on engines, performance, or design. But if you take a closer look inside and outside of a vehicle, you'll notice that plastic parts play a huge role. From dashboards to bumpers, from light covers to small clips hidden under the hood, plastics are everywhere. One of the main ways these parts are made is through a process called automotive injection molding.

What is Automotive Injection Molding?

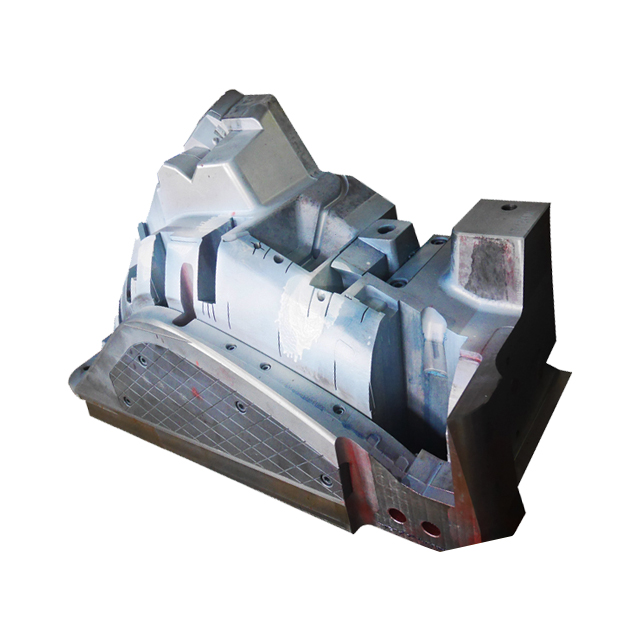

Automotive injection molding is a manufacturing process used to create plastic components for vehicles. It involves melting plastic pellets and injecting them into a mold cavity under high pressure. Once the plastic cools and hardens, it forms the shape of the mold. This process is highly versatile and makes it possible to produce everything from large structural pieces to tiny functional clips with consistent quality.

Automotive injection molding is especially valuable in the automotive world because it can produce complex parts quickly and at a relatively low cost. With injection molding, automakers can design lightweight, durable, and cost-effective components that meet safety and aesthetic requirements.

Why Plastic Parts Matter in Cars?

Decades ago, cars were mostly made of steel and other metals. Today, plastics account for a large portion of automotive parts. Here's why plastics have become so important:

Lightweight advantage – Reducing vehicle weight improves fuel efficiency and supports electric vehicle (EV) performance by extending driving range.

Cost savings – Plastic parts are usually cheaper to produce and easier to shape than metal components.

Design flexibility – Injection molding allows designers to create unique and complex geometries that would be nearly impossible to make with traditional metalworking.

Durability and safety – Modern plastics can withstand heat, stress, and wear, making them suitable for interior and exterior parts.

Sustainability – Many injection-molded plastics can be recycled or made from recycled materials.

Key Applications of Automotive Injection Molding

Automotive injection molding touches almost every part of a vehicle. Let's go through some common applications.

1. Interior Parts

● Dashboards

● Center consoles

● Door panels

● Air vents

● Cup holders

● Seat belt components

These parts not only need to look appealing but also must withstand constant use and exposure to temperature changes. Injection molding helps achieve a consistent finish across all interior elements.

2. Exterior Parts

● Bumpers

● Grilles

● Light covers (headlights, tail lights)

● Side mirrors

● Wheel trims

Exterior plastic parts require strength and resistance to weather, UV light, and minor impacts. Automotive injection molding provides the necessary durability while keeping costs manageable.

3. Under-the-Hood Components

● Engine covers

● Battery housings

● Fluid reservoirs

● Clips, brackets, and fasteners

These parts need to resist heat and chemical exposure. Specialized high-performance plastics, molded through injection processes, are used here.

4. Electronic and Sensor Housings

As cars become smarter and more connected, plastic housings for sensors, radars, and cameras are in high demand. For example, car electronic radar sensor housings are commonly injection-molded to protect sensitive electronics from dust, moisture, and vibrations.

How the Automotive Injection Molding Process Works?

To better understand why this process is so popular, let's look at the main steps:

1. Design and Prototyping: Engineers create 3D models of the part. Prototypes may be developed using CNC machining or 3D printing to test form and function before moving into mass production.

2. Mold Creation: A mold is built, often from steel or aluminum, to match the exact design of the part. This mold is the key investment in the process, and its precision determines the quality of the final product.

3. Material Selection: Automotive injection molding uses materials like polypropylene (PP), acrylonitrile butadiene styrene (ABS), polycarbonate (PC), and nylon (PA). Each material is chosen based on its strength, flexibility, and resistance to heat or chemicals.

4. Injection Molding Process

● Plastic pellets are fed into a heated barrel.

● They melt and are injected under pressure into the mold.

● The material cools and solidifies in the shape of the mold cavity.

● The mold opens, and the finished part is ejected.

5. Post-Processing and Quality Control: Some parts may need additional steps like trimming, coating, or painting. Every part goes through inspections to ensure it meets quality standards.

Benefits of Automotive Injection Molding

The reason this method is so widespread is that it offers unique advantages:

High precision – Perfect for parts that require exact dimensions.

Scalability – Once the mold is made, thousands of identical parts can be produced quickly.

Lower labor costs – The process is highly automated, reducing the need for manual labor.

Consistency – Every part comes out nearly identical, which is critical for automotive assembly.

Material efficiency – Minimal waste compared to other manufacturing methods.

Why RUNKE is a Trusted Partner in Automotive Injection Molding?

When it comes to turning designs into reliable products, RUNKE has established itself as a strong partner for global automotive brands. Over the years, RUNKE has supported automakers with:

Mold of light cover production – Ensuring high transparency and durability for headlight and taillight covers.

Car electronic radar sensor housings – Providing precision-molded protection for advanced driving systems.

Car internal plastic parts – From dashboards to smaller connectors, RUNKE delivers parts that meet both functional and aesthetic needs.

What sets RUNKE apart?

Quick-turn manufacturing – Short lead times to help automakers move fast.

Automated DFM (Design for Manufacturability) feedback – Engineers optimize designs before production to avoid costly issues.

Prototyping and low-volume production – Perfect for testing designs or creating specialized parts.

Mature supply chain – RUNKE helps automotive brands respond to market changes quickly and efficiently.

By combining technical expertise with advanced facilities, RUNKE reduces risks and expenses for its customers, making us a go-to partner in the automotive injection molding industry.

Conclusion

Automotive injection molding is one of the most important manufacturing processes in the automotive industry. From interiors to exteriors, under-the-hood parts to sensor housings, it plays a role in almost every part of a vehicle. It provides automakers with the ability to produce lightweight, durable, and cost-effective parts at scale.

Auto accessory mold manufacturers like RUNKE make this process even more efficient by offering quick-turn manufacturing, optimized designs, and a strong supply chain. Whether you’re developing prototypes, low-volume runs, or large-scale production, RUNKE is a reliable partner to bring automotive plastic parts to life.

.jpg)

.jpg)