Discover the cost of plastic injection molds across industries like automotive, medical, electronics, and more. Learn what affects mold pricing.

.jpg)

Discover the best materials for injection molding—from ABS and Polypropylene to PEEK and sustainable plastics.

Injection molding for Class III medical products stands out as a reliable manufacturing method that ensures consistency, and precision in producing medical components.

Motorcycle injection molding offers unmatched versatility, accommodating a wide range of materials.

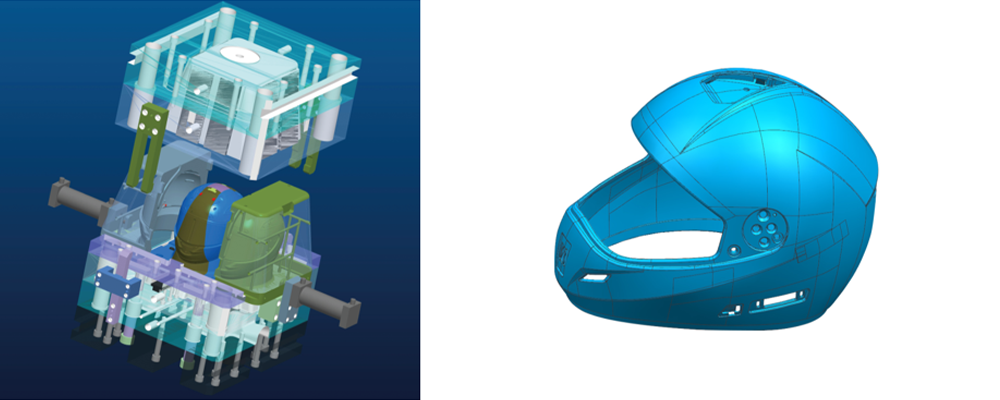

Motorcycle helmet molds are an important factor in ensuring the safety of riders, as they help to create helmets that are strong, and durable.

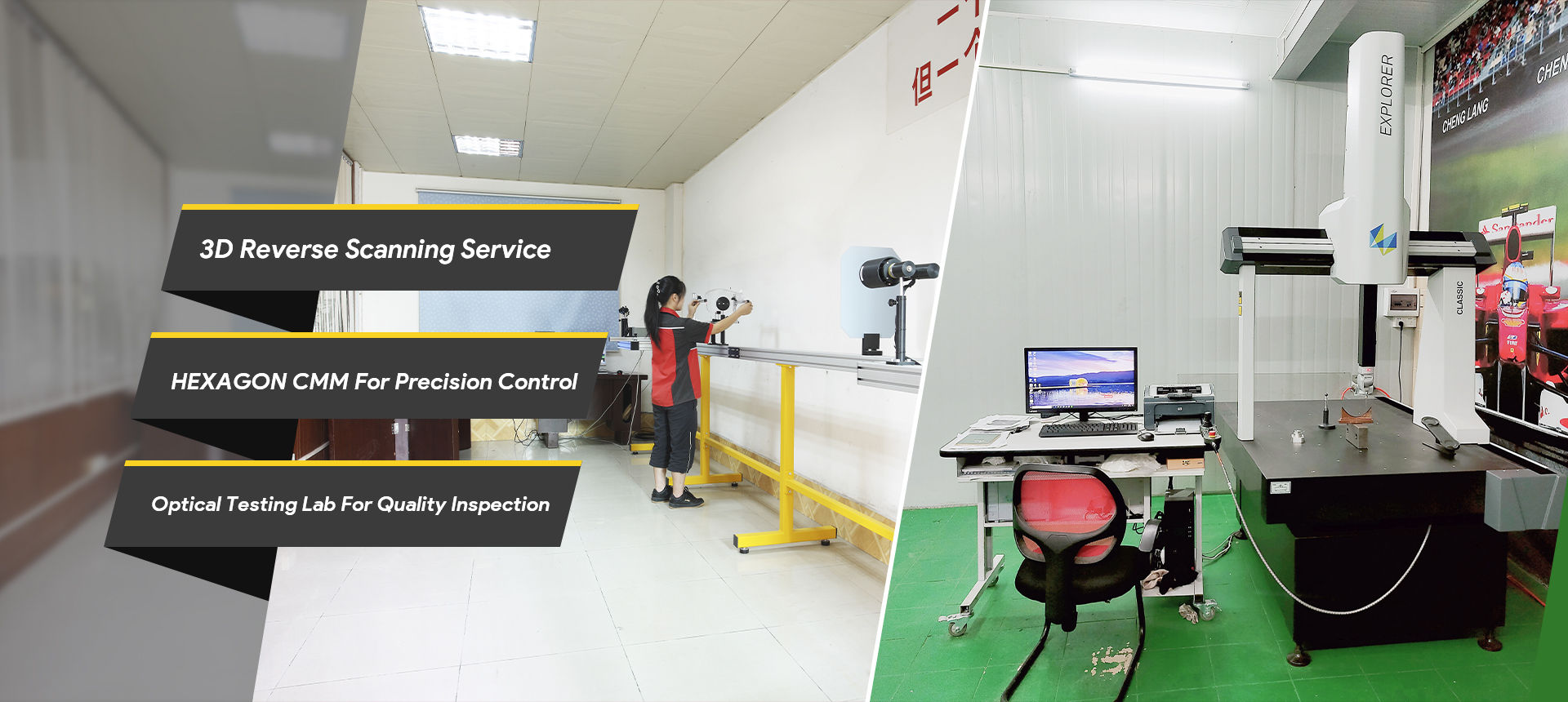

Explore types, manufacturing processes, and the vital role of motorcycle plastic injection molds. Trust RUNKE for high-quality, custom mold solutions.

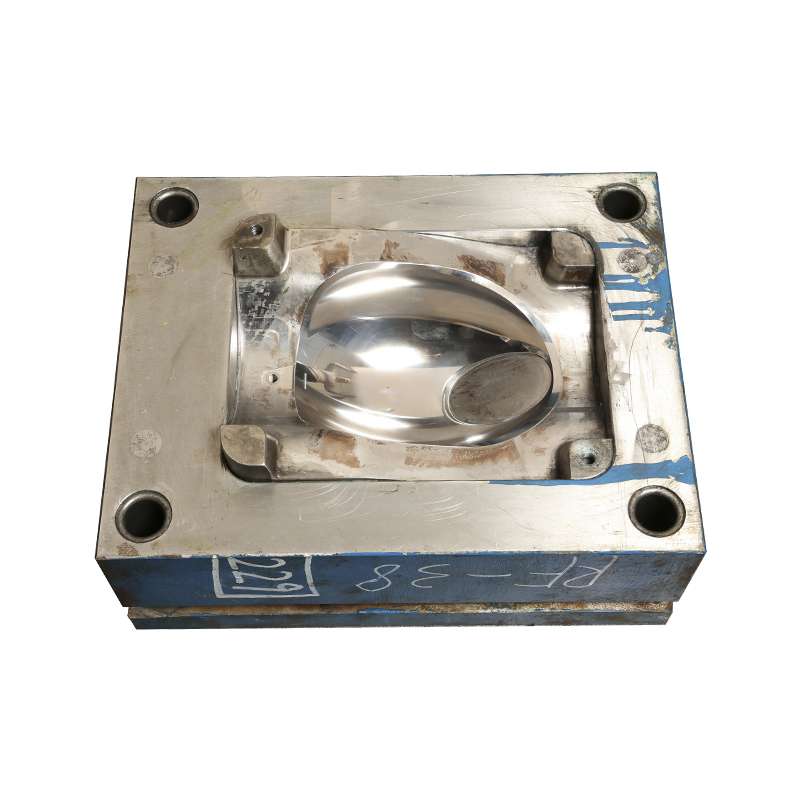

Learn how precision kettle mold enhances efficiency, durability, and quality in kettle production. Contact RUNKE for custom molding solutions.

Discover how CNC machining ensures high accuracy in precision electronic mold manufacturing.

Discover solutions for common motorcycle injection molding issues like sink marks, short shots, warpages, and more to ensure high-quality parts.

Discover how medical plastic injection molding enhances the precision manufacturing of safe medical devices through advanced techniques and quality control measures.